FlexStyle® Beveled provides a uniquely textured appearance, with angled geometric designs sure to turn heads! Offered in metallic and non-metallic finishes.

FlexStyle® is perfect for hard goods, outerwear, and heavy-duty garments with its heat-sealing and pressure-sensitive applications to adhere to various surfaces.

Don’t forget your FlexStyle® Silicone Pad to protect your emblem and garments!

Hardgoods, Hats, Outerwear

Minimum: 1"x 1"

Maximum: 3.75" x 5"

Thickness - 1.5mm (+/- 0.5mm)

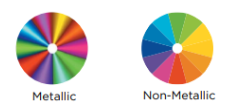

Color

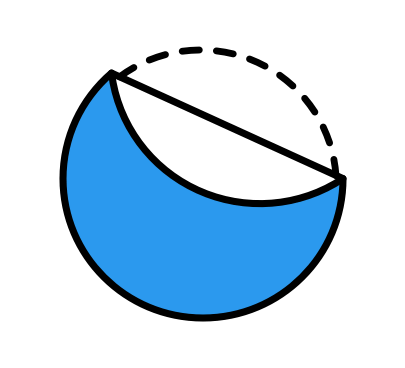

Backing

Limitations

Low melt - Recommended application for thicker materials, such as jackets, and hats that can withstand a heat press and 320° F. Not recommended for use on materials that may be heat sensitive (ex: some nylons, silk, some plastics, leather, wool, fleece, etc.) or for weather-treated materials, due to chemicals used that do not allow the emblems to adhere properly.

Pressure-sensitive - Recommended application is on flat, non-textured surfaces, including glass, plastic, wood, and metal. Not recommended for application on surfaces that may contain an oil finish, such as silicon, Teflon™, rough fabrics, or outdoor goods.

Floating Elements

Minimum size raised within an element - 1mm

Minimum size floating - 4mm

Textures

In some cases, it may be necessary to add some regular texture in the artwork. Our trained designers will determine the best option to incorporate this texture according to the needs of the product.

Washing Information

FlexStyle® emblems will withstand at least 25 domestic washing machine cycles at 104°F max.

Shelf Life

One year shelf life before applying (room temperature-controlled environment).

Revised 11.26.24

LOW MELT BACKING WITH A 360 IQ™ HAT HEAT PRESS - HATS

LOW MELT BACKING WITH TOP HEAT & BOTTOM HEAT - GARMENTS

LOW MELT BACKING WITH A TOP HEAT PRESS - GARMENTS

Disclaimer

World Emblem recommends testing the best combination of heat seal parameters before application. World Emblem is not liable for any damages to garments during the application process.

Note: Please check out www.youtube.com/worldemblem for step-by-step instructions for applying our apparel decorations.

PRESSURE-SENSITIVE

Pricing

Using the drop-downs above, you can find the approximate price per item, based on the emblem size and quantity ordered.

To determine the size of your emblem, use the following formula:

Size = Width + Height / 2

Price Includes

Add-ons

Electronic Proof

A digital proof via email is available in 1 day. Edits are allowed.

Set-up Charges

One-time mold charge and artwork fees (includes up to 5 samples and overnight shipping).

Production Time

Samples will take 2 days plus shipping. Production time will take 4 day plus shipping on an order up to 2,500 pieces. Add 1 day per 2,500 pieces.

Click HERE to view our Products & Services Turnaround Times table for your convinience.

NOTE: All turnaround times are subject to change. Larger orders may result in additional business days for production. Orders received after the cut-off time will be considered as received the next working day.

Proposition 65 requires businesses to provide warnings about significant exposures to chemicals that cause cancer, birth defects or other reproductive harm. These chemicals can be in the products in homes or workplaces, or that are released into the environment.

The CPSIA strengthened children's product safety by establishing critical safety and traceability requirements.

Primarily, CPSIA regulations enforce:

Rigorous restrictions on phthalates

Rigorous lead restrictions

Requires acceptable levels for several substances common in most consumer products, especially those designed for children, ages 0-12.

Our patches can be applied in-house with low-melt heat seals - saving you time and money on shipping.

Review a digital proof shortly after submitting your design to avoid any design surprises.

Our design team is here to help. We offer a range of services to help you take your ideas from sketches to reality.

Looking for custom patches for jackets or other outerwear? Increase your brand’s exposure in any weather with FlexStyle® Beveled - our most durable emblem to date. Giving your logo a sharper, more refined look, the beveled edges add dimension to any design.

Our instructional videos walk you through proper product applications, equipping you with the knowledge you need to enhance your brand with FlexStyle® Beveled.

Take your brand to the next level with our variety of high-quality products. Explore our most in-demand patch styles, from embroidered and PVC to woven and leather. Whether you're looking for bold colors, clean die-cuts, or standout textures, World Emblem offers the high-quality custom patches your brand deserves.